SEGARC650 CHROMIUM-CARBIDE OVERLAY PLATE

SEGARC650 is a unique abrasion resistant chromium-carbide overlay on a mild steel base plate. It is designed for areas with moderate impact and severe abrasion. This plate can be cut, formed, or rolled. Our unique overlaying process produces a plate with a surface that is harder, tougher, and more wear resistant than plate made by any other process. SEGARC650 can be formed or rolled. SEGARC650 is available in thicknesses from 1/4” to 1”. SEGARC650 must be cut by plasma or abrasive water jet.

Hardness: 58 to 62 Rockwell C

Service Temperature: 1000 degrees (F)

Welding Procedures:

SEGARC650 is normally supplied with plasma cut edges and can be welded in place to carbon steel structures with a low hydrogen rod or wire such as E7018 or E8018. No preheating is required. It may be necessary to hardface over the weld with SEGARC101HC wire for added protection.

Standard Sizes:

Standard plate size is 60” X 120.” SEGARCS650 can be cut to your specific needs. SEGARC650 is available in single, double and triple pass applications in special thicknesses or on special bases upon request.

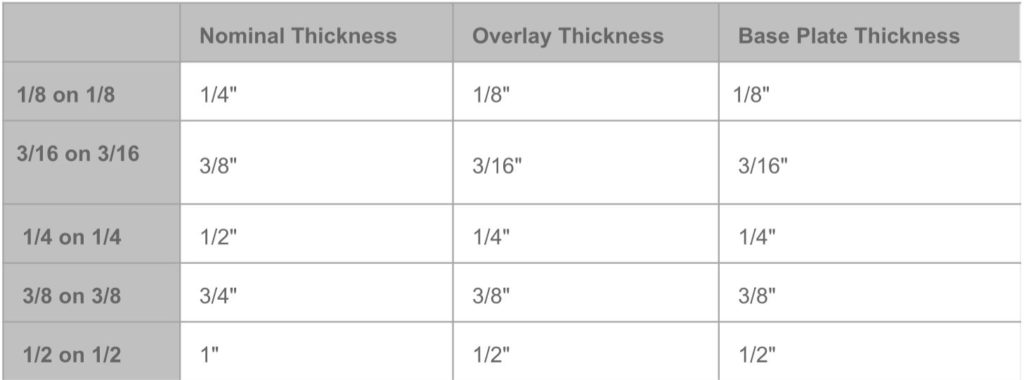

Standard Thicknesses are:

Suggested Uses for SEGARC650 Wear Plate:

Chutes

Conveyors & Liners

Crusher Components

Cyclones

Dozer Blade Liners

Debarking Drum Components

Drag Conveyors

Drums & Sprockets

Dust Collector Systems

Flights

Fan Blades & Housings

Flatback Elbows

Flume Liners

Hammer Mill Side Liners

Heel Pads

Haul Truck Bed Liners

Hooks

Hot & Cold Stip Mill Guides

Impact Plates

Liner Plates

Log Decks

Mine Cars & Equipment

Sand Systems

Scraper Blades

Screens

Shakeout Machines

Scrap Handling Equipment